Machineries

FILTER CLEANING STATION

DE-DUSTING TUNNEL

DOUBLE CONE BLENDER

PNEUMATIC CONVEYING

DUST COLLCETION SYSTEM

BELT CONVEYOR SYSTEM

DEN

MIXER

HOT GAS BY PASS VALVE

SULPHUR EJECTORS

WASTE CONVERTOR MACHINE

FLUE-GAS DESULFURIZATION

FILTER CLEANING STATION

These systems are generally used for cleaning of HVAC filters to avoid cross contamination of the dust generated while preparing different medicine batches.

The system is automated and the process consists of air wash, water wash, detergent wash, dewatering & drying. The system comes with a dust collection system for collection of the dust release during washing/ cleaning of the filters.

DE-DUSTING TUNNEL

The system is used for cleaning of bags and containers. The system assures the removal of foreign dust particles which has developed on the surface of the bags/ containers during various level of transportation. The system consists of a set of specially designed air spray nozzle to clean at an 360 degree area. The system comes along with a dust collector to collect the dust while cleaning.

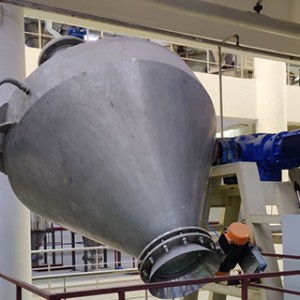

DOUBLE CONE BLENDER

DOUBLE CONE BLENDERS as specifically used for mixing of different material for required specific mix as per the process requirement. The system comes with an automated filling of material and liquid as per process and can be operated using SCADA or HMI interface.

PNEUMATIC CONVEYING

The system is basically used for conveying of different type of powders / granules of different density using a positive displacement blower or compressed air. A lean phase or dense phase system are used as per moisture content and particle size of the product. Material can be used to transfer products at various distances through pipe network.

DUST COLLCETION SYSTEM

Our Dust Collection systems range from 250 CMH to 1 Lac CMH with reverse jet, self-cleaning arrangements and filter media as per the various dust quality. The system can also be provided with anti-static filters and flame proof instrumentation.

BELT CONVEYOR SYSTEM

Our Belt conveyor systems are customizable in various width and length as per our clients’ requirements.

DEN

The Heart of Single Super Phosphate Plants. Our clients have reached optimal production capacity with our Den provided with all T-Slats, R.P. Den, fixed den, discharge chute, shafts of main rotating den, cutter shaft, R.P. Den shaft, pulleys & motor gear box.

MIXER

Mixer is a two chamber equipment with a kneader at the mixer end. Sulphuric Acid, Phosphate and water is mixed here with the help of paddles. Slurry mixture is pushed into the Den through a chute.

HOT GAS BY PASS VALVE

The function of a Hot Gas By Pass Valve is to bypass hot gas across the waste boiler to achieve temperature control on the convertor.

SULPHUR EJECTORS

We are market leaders in Self Cleaning Type Sulphur Ejectors to ease the maintenance and operation functions of our clients.

WASTE CONVERTOR MACHINE

We are market leaders in Self Cleaning Type Sulphur Ejectors to ease the maintenance and operation functions of our clients. Our machines have a capacity to treat 6 to 60 kg of organic waste per batch.

FLUE-GAS DESULFURIZATION